Back to top

Hot deals

Best place to stop and buy reliable Agricultural Implements such as Maize Thresher, Multi Crop Thresher, Groundnut Thresher, Rotavator, etc.

An Introduction

Jangeer Manufacturing Industries Private Limited was formed when in year 2005, Sardaar Jangeer Singh firstly invented a normal thresher that used to work with tractor and separate wheat from chaff. With the passage of time, this invention turned into to a successfully company, which we are today. We are among the top manufacturers and exporters of Multi crop Thresher, Rotavator, Groundnut thresher, Maize Thresher etc. These are engineered from durable material along with employing latest technology of the industry.

We always prioritize quality over quantity as a result we deliver the most reliable and well-performing agricultural implements. Due to our products quality and fair trade practices, we have made network of our dealers in Madhya Pradesh, Karnataka, Rajasthan, Gujarat and Maharashtra.

We always prioritize quality over quantity as a result we deliver the most reliable and well-performing agricultural implements. Due to our products quality and fair trade practices, we have made network of our dealers in Madhya Pradesh, Karnataka, Rajasthan, Gujarat and Maharashtra.

Infrastructure

To develop a quality range of threshers and other agricultural implements in a streamlined manner, we have developed a sound infrastructure. In the premises, we have latest manufacturing equipment such as:

- Robo Cutting Machine

- Plasma Cutting Machine

- CNC Machine

- VMC Machine

- HMC Machine

- Liner Welding etc.

To ensure that our machines remain in proper working conditions, we periodically upgrade and overhaul them.

Design Engineering

We pay emphasis on creating agricultural implement of such designs that carry engineering excellence. Our Agriculture Wheat Thresher, Maize Thresher, Groundnut Thresher, Metal Agriculture Rotavator and all other products are developed after analyzing their usage. We ensure to build products in such structure that promises to lasts for a longer time.

Quality Assurance

Quality Policy

At our premises, we are following a policy, which makes us pay high attention on the quality of products. Each stage of product development is supervised by our quality team, which guarantees impressive results. Our R&D team constantly looks for market developments & trends and further updates quality team about it, so that the best can be developed for customers. The team also conducts tests that once cleared, range is proceeded further. They firstly examine the construction of our agricultural implements and then sharpness of blades that are used in threshers.

To have the best quality, we make sheet and shaft of our products with the help of CNC machine. Further, we use VMC machine for developing gear box and wheel balancing machine to check the balance of wheels. Our experts employ MIG welding machines to develop main parts of machines like chassis, rotor, etc.

All the machines that we offer have C&D V belt of high quality. We also make use of TR or JIP bearing after testing quality of them in our lab. Further, full heavy duty gear box is used by our experts to develop thresher, which can carry small load and; tractor that consume less diesel. To obtain high quality, we also ensure that fresh pieces of ball bearing are used.

Our Values

Our organization has adopted certain values to run its business, some of them are:

- Integrity

- Professionalism

- Accountability

- Honesty

Environment Policy

We realize our responsibility towards environment and we take several measures to ensure that we prevent pollution and promote environmental compatibility. At our premises, modern technology is used and several steps are taken to ensure that we do not harm nature while carrying out our trade processes.

Safety Policy

For us, our employees are like a family members. We are committed to work in a safe manner and ensure safety of the employees. We maintain injury free work environment and abide by the associated laws and regulations. Further, at our premises, we encourage development of safe work attitudes, conduct safety programs and follow several standards to ensure that experts remain safe while carrying out their tasks. By providing such safe and secure environment to employees, we regularly bring forth the best Metal Agriculture Rotavator, Wheat Thresher, Maize Thresher, Groundnut Thresher, etc.

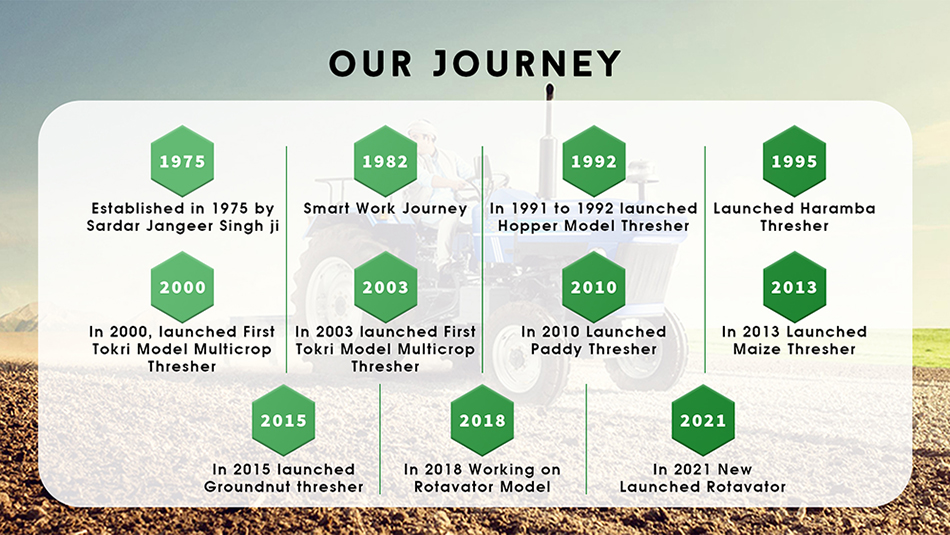

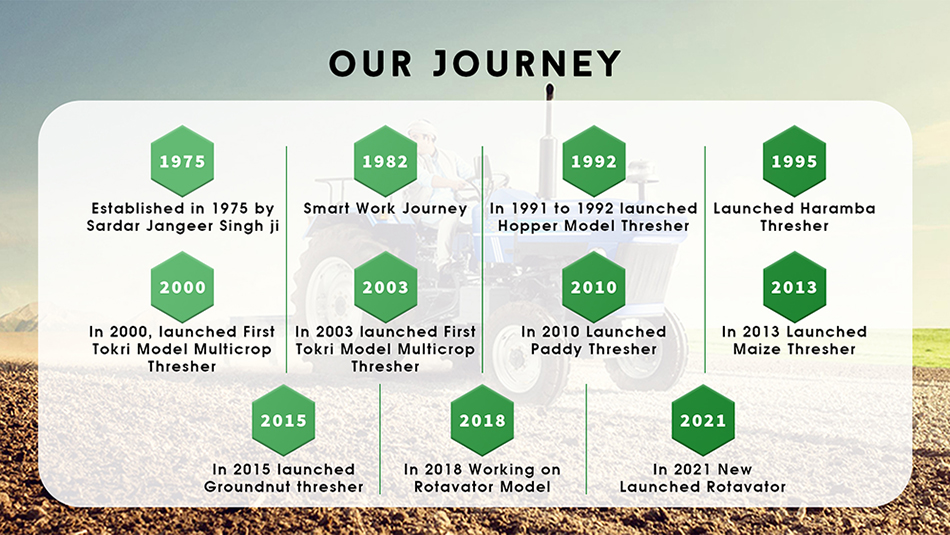

Our History

In year 1975, Sardar Jangeer Singh ji along with his family moved from his village, Kabulshah Khubhan, which is in Indist. Firozpur, Punjab to settle in Raisinghnagar. At that time, he began developing bull carts and animal's cart. Later, he switched to steel work from wooden work for making cart. After this, he started manufacturing several types of agriculture equipment such as cultivator, plough, spray pump, disc harrow etc.

In the year 1984, he got the support of his eldest son, Gurmeet Singh, who joined the business. After learning skills and getting inspired from passion & hard work of his father, Gurmeet Singh started creating some of new implements like spray pump, MB plough, etc. In 1991, Jangeer Singh, who is the second son of Gurdeep Singh joined the business. In 1992, together they developed the hopper model thresher.

With time, they adopted technology and came up with new advancements in various implements such as automatic cotton seed drill, seed drill, folding spray pump, etc. In 1995, they developed Hadamba Thresher, which got high popularity and extensive demand in the market.

In the year 2000, brothers, Gurmeet Singh and Gurdeep Singh got attention of tokri mode Multi-crop Thresher and together they started working on it. In 2003, first tokri model multi-crop thresher was launched by them. The thresher got excellent response from customers and as a result high demand from market. They continued the hard work and brought regular improvements in it.

The passion and dedication they carried for bringing improvements in machine helped us develop the best threshers. Further, in the year 2010, Paddy Threshers were introduced and Maize Threshers were developed in 2013. In the year 2015, the company came up with new Groundnut Thresher. We develop different models in Multicrop Thresher as per different market conditions. We began our journey from small city, but today, our machines are demanded across all the corners of India.

Most Popular Products

Send Inquiry

Send Inquiry Send SMS

Send SMS